Marc Michel, an associate professor of geosciences in the College of Science, typically spends his days studying nanoparticles. He seeks new water treatment methods and ways to create untapped sustainable energy resources.

Digitally printing thousands of nasopharyngeal swabs to be used by medical clinics during the pandemic was not on his mind when 2020 started. Michel’s use of 3D printing technology typically includes fabricating custom reactors and other laboratory devices. But medical tools? No.

“I just wanted to be useful and knew that I could add something based on my experience in computer-aided design and 3D printing,” said Michel, who serves as head of the Nanoscience program in the Academy of Integrated Science in the College of Science.

In mid-March, Michel began work on a project to use 3D printing to retrofit off-the-shelf snorkel masks into full-face PPE masks. The project was aimed at supplying front-line responders with protective head gear, but was overtaken by a more pressing need: a shortage of nasopharyngeal swabs, brought to Michel’s attention by Carla Finkielstein, of the Virginia Tech Molecular Diag-nostics Laboratory. Finkielstein was dissatisfied with swabs typically used in testing. She had identified a better design and reached out to Michel, knowing he wanted to help.

“This was particularly important to the COVID world of molecular diagnostics as standard swabs do not meet the requirements for nucleic acid isolation,” Finkielstein said in June. “Marc produced the first prototype, and I tested its efficacy for collecting biological samples and nucleic acid isolation. The mechanical properties and clinical performance of the 3D-printed swabs were comparable to commercial ones. The result of Marc’s work is one we can all benefit from, a reliable product that can be used for our specimen collection, and that is fabricated in-house and on-demand.”

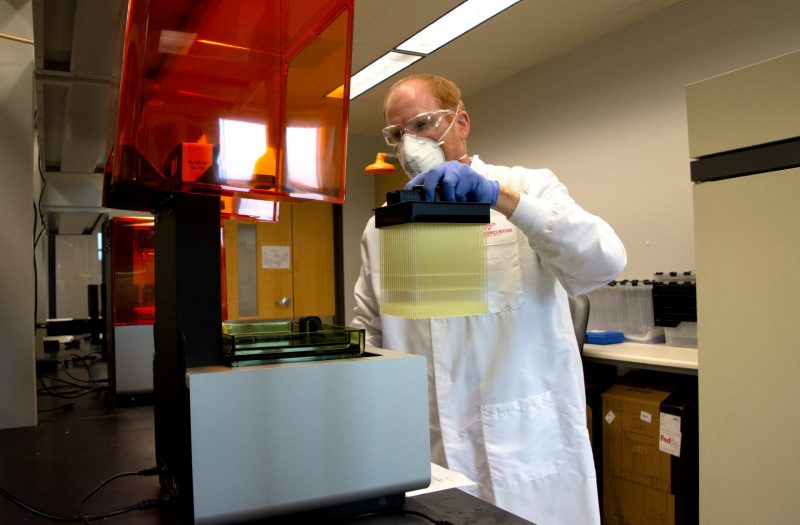

Michel’s lab uses a particular type of 3D printing known as inverse stereolithography, where a laser light turns thin layers of liquid polymer into a solid plastic. These were the same printers used to manufacture two swab designs developed by the University of South Florida in collaboration with New York-based nonprofit North-well Health and the Massachusetts-based 3D printing company Formlabs, Inc. “I knew that the 3D printers in my lab were suitable for printing the USF design, so I volunteered to take the lead,” said Michel, who is also a Luther and Alice Hamlett Junior Faculty Fellow.

Work by Michel began in a temporary 3D printing shop set up in his home basement, before switching to a lab at Steger Hall, part of the Fralin Life Sciences Institute. The process for printing is complicated, but the work must meet federal medical and safety standards. The printing process begins with duplicating a digital model to create 324 swabs arranged in a square pattern of 18-by-18 rows. Each build takes about 15 hours to complete, as the swabs are printed layer-by-layer, with each layer 100 microm-eters in thickness.

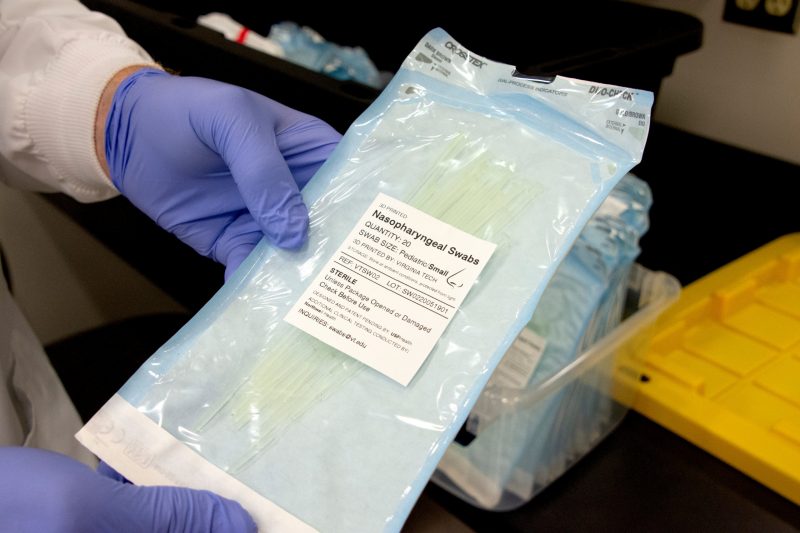

The completed parts are then rinsed in isopropanol to remove uncured resin on the surfaces, dried, and then removed. Then, Michel individually inspects the swabs as they are mounted on a curing rack. The swabs are then “cured” for 30 minutes in a chamber that completes the polymerization. Lastly, the swabs are sorted into plastic pouches, sterilized, and then labeled.

To meet federal standards, Michel, Finkielstein, and additional teammates worked with Robert Gibson, associate director of business development at Fralin Biomedical Research Institute and with Virginia Tech’s Link + License + Launch. Gibson contacted Christians-burg, Virginia-based SGS Polymer Solutions lab to profes-sionally test the swabs. “You’ve got to have third-party tests of these swabs for some external assurance the swab works and won’t hurt anyone,” Gibson said.

The swabs passed.

Others who helped include Assistant Professor Michael Bortner of the Department of Chemical Engineering, Professor David Dillard of the Department of Biomedical Engineering and Mechanics, and 3D printing expert Christopher Williams, the L.S. Randolph Professor in the Department of Mechanical Engineering; Michael Friedlander, executive director of the Research Institute at VTC and Virginia Tech’s vice president for health sciences and technology; and Hal Irvin, the associate vice president for health sciences and technology outreach for Virginia Tech.

Much of the funding to support Michel’s work came from the Virginia Tech Office of the Vice President for Research and Innovation’s COVID-19 response funds. All of this work, of course, took place as Michel maintains his daily research and grant writing efforts, converts previously in-person classes to online instruc-tion, and juggles three young children with his spouse, Nieves.

Contingent to FDA approval of a new COVID-19 testing array system by Finkielstein, the testing swabs will be used on hundreds of Virginia Tech students, faculty, and staff once the fall semester kicks into gear and in-person class sessions begin. Regional health clinics also can use the swabs as needed.

“As we are experimentalists, this pandemic has forced us to look at our research differently, and has led us to pursue what I think are very exciting directions that use novel approaches,” Michel said. “I definitely see the swab project as an added bonus, since it is a chance to add something significant to collective efforts to stem the damage of this pandemic.”